Park Min-suk in Berlin, May 2014

People in their thirties and early forties usually have a broad range of topics to talk about: spouses, kids, work, etc. But when Mrs Park Min-suk (41) gets a phone call from old friends, it is often about her friends getting cancer. Park herself was diagnosed with breast cancer in 2012. It was those phone calls that made Park suspect their common work place as the cause of the diseases. She used to work in wafer fabrication cleanrooms of Samsung Semiconductor for more than 7 years. Of the 18 collegues of her shift, 7 were diagnosed with cancer and reproductive diseases. We met her in Berlin, together with Dr. Kong Jeong-ok from SHARPS who helped with the translation.

Faire Computer: Do you still work at Samsung?

Park Min-suk: Not now, I worked at a Samsung factory from 1991 to 1998. That’s 7 years at Samsung. I was born in 1973, and entered the factory at the age of 18.

FC: What was your job?

Park: I worked in the production line of wafers, in different processes, like dry and wet etching, which means to remove chemicals, for example photoresists, which were put on the wafer in order to develop and then cut it. That wafer should be cleaned by some chemicals, that is the etching process. I also worked in CVD process and thin film process, too. I worked rotating in different production lines.

Initially, Park’s job was to clean these wafers. A senior worker introduced her to the job. Safety was only mentioned with regards to the wafers, each one „costing as much as your house“, emphasized a senior worker.

Park: Acetone and isopropyl alcohol were the most frequently used in order to clean the work station. I directly handled those chemicals every day.

FC: Did you know that those chemicals are dangerous?

Park: I didn’t know anything about the hazards. Though I handled many different chemicals and gases, I just believed what the company told us. They said that the cleanroom was perfectly managed, so we didn’t think about chemical hazards at all. I only vaguely felt that it may be dangerous. Before I got the job, I heard that strong electro-magnetic fields used in semiconductor factories could threaten female fertility.

Semiconductors are produced through very complex procedures. Usually, etching chemicals are used to inscribe the circuits onto a wafer, a thin slice of a semiconducting material. Dust is very harmful to the chips, that’s why they are made in cleanrooms. In order to protect the electronics from hairs, dust and saliva, workers have to wear bunny suits – as famous since Intel’s TV advertisment starring jumping cleanroom workers. Although looking like a space suit, these suits are rather not designed to protect the worker. In fact, while they prevent human particles from contaminating the wafer, they do not prevent chemicals from entering the human body at all.

Park worked at Samsung’s semiconductor factory in Giheung, Korea, producing memory modules, for example 64 MByte DRAM or 256 KByte Fast SRAM. If you possessed an ordinary desktop PC from that time, chances are that it was running with memory modules made by Mrs Park and her collegues. As of today, Samsung is no. 1 in the world’s production of memory chips.

FC: Did you talk with your colleagues about the chemicals?

Park: No co-worker told me. When we entered the factory, one of the senior workers – we called them „sister“ – taught us how to work in detail. It is a kind of teacher or parent for the young workers. If they don’t mention anything about the dangers, the younger worker have no reason to suspect any.

The senior workers used their authority for the good of the wafers. In case an accident would happen, Samsung even had their own interpretation of an evacuation plan, as Park explains:

The biggest danger that I heard of from the sister was about the „shutdown“. That means that the production facilities are stopped for maintenance or because of a power blackout. They told us that this the most harmful moment for the wafers – not for the workers – and if you escape from that dangerous situation without taking care of the wafer, the remained wafer could be damaged due to exposure to too high levels of chemicals. The wafer should be evacuated before the workers leave, that’s what we always should remember.

Park did so well on the job that she became a team leader. The first three years with Samsung were quite busy. Employees were expected to work every day, each month they could take a single day off, provided that a colleague would do the work of two persons for a shift.

She and her colleagues had been in their early twenties then, some of them still teenagers, all women.

FC: Did you suffer from illnesses during or after working at Samsung?

Park: I suffered from stronger menstrual pain. In the cleanroom the air pressure was very high, so I got very tired. I remember the life at the factory as working and going back to the dormitory to sleep. Just working and sleeping, nothing else, even in my early twenties. I was very exhausted.

For the first three years, we only had a single day off per month. In order to take that day off, another worker had to take a double workload. We really needed the day off, but we could make it only one day per month, because we could not do this ‚twice working‘ more than one time per month.

I left the factory when I married, but I couldn’t have a baby for 4 years. I had a miscarriage in that time. Everything went well after I had my first child in 2002, but in 2012, when I was 39 years old, I was diagnosed with breast cancer.

FC: Did something like this also happen to your co-workers?

Park: Yes, because I was a team leader, I heard many stories.

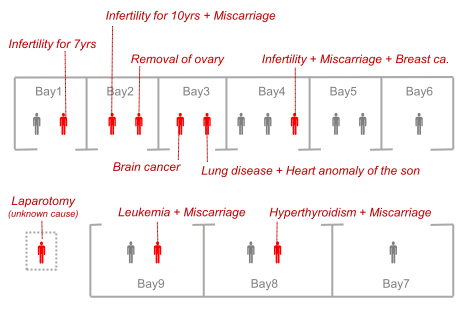

Park starts drawing a diagram of the Fab Lab, the fabrication line she worked at during the first three years at Samsung. There are 9 work stations, called „bay“, most with 2 workers in 3 shifts, each bay 6 workers in total.

End-Fab (1991 – 1994) at Samsung Semiconductor based on picture by Mrs Park. Click to see the original draft.

She explains what has happened to the members of her team and lists various reproductive problems and cancer cases. Her team consisted of eighteen workers, one third out of the 54 workers in the line, and at least 7 of them got sick.

An exceptionally high rate of mostly rare diseases.

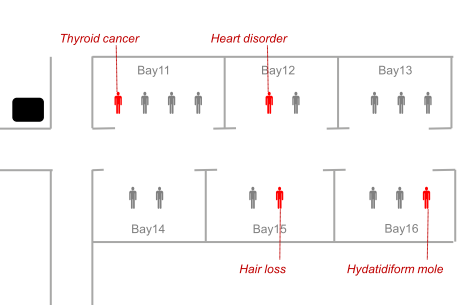

Park: I don’t know about the health of the other 44. In my team, there were cases of infertility, for 7 years and more, brain cancer, leukemia, hyperthyriodism and miscarriage, one woman even had her ovaries surgically removed before she married. In 1994, Samsung constructed a new production line with a different setup of bays and workers. After that time, I had co-workers who got thyroid cancer, molar pregnancy, and hair loss at a very young age.

FC: All this happened at the same place?

Park: Yes, these are all cases from a single fab. There were more cases at other production lines. In January 2014, a female leader from a different production line using photo chemicals just died of stomach cancer at the age of 42. A male production engineer died of leukemia, also in his forties.

FC: Has there been any investigation on behalf of Samsung about the illnesses?

Park: I haven’t heard anything about that. I only remember that they raised money from the employees to support one of the employee’s fight against an illness. The company made a kind of fundraising for its worker.

Normally, Korea Workers‘ Compensation and Welfare Service (KCOMWEL) would compensate the workers if their disease is considered to be work-related. As Samsung neglected responsibility for the sick workers, welfare in most cases has not been paid. In South Korea, health insurance does not cover therapy costs completely. Patients have to pay their own contribution which is often about 50%. Many sick Samsung workers ran into debts when they had to pay for their own treatments.

FC: Did you file a lawsuit?

Park: No. In July 2013, I made a claim to the government to get the workers compensation. They’ve not answered yet, after 10 months. I keep waiting. Samsung never contacted me.

Only recently Samsung in May 2014 admitted responsibility for the illnesses of their employees, sending out a halfhearted apology. The tedious negotations are more long-living than some of Park’s colleagues, who already have died.

Park’s cancer is under control for now. She is working again – in a school for disabled children. She says she’s happy there.

Park Min-suk appearing in the documentation „The Empire of Shame“ (CinemaDAL, 2013)

Note by the editor: In a forthcoming article, we will continue the story with an interview with Dr. Kong Jeong-ok and cover the work of SHARPS, a group of Korean semiconductor workers, their relatives, attorneys, unionists, and physicians who made the cancer cluster at Samsung public. If you have questions, feel free to get in contact via fairit @ fiff.de

(Eine deutsche Version dieses Artikels ist unter http://blog.faire-computer.de/krebserkrankung-auf-samsungs-karriereleiter/ zu finden.)

A picture of the factory in Giheung is here: http://cnet3.cbsistatic.com/hub/i/r/2013/10/25/1299395f-6de6-11e3-913e-14feb5ca9861/Samsung_Giheung_04.jpg

I found Giheung mentioned also in a Hankyoreh article from 2012: http://english.hani.co.kr/arti/ENGISSUE/74/416380.html

Although Samsung now offered plans for compensation, Mrs. Park won’t join it because her cancer has been diagnosed 14 years after she left Giheung. Samsung requires at most 10 years. Source: https://stopsamsung.wordpress.com/2015/04/07/barely-3-out-of-10-victims-qualify-for-samsungs-compensation-plan-standards/

Pingback: auto accident attorney omaha ne